The Castec Shoring Wall Advantage

Performance Comparison - Engineering Snapshot - Where Used

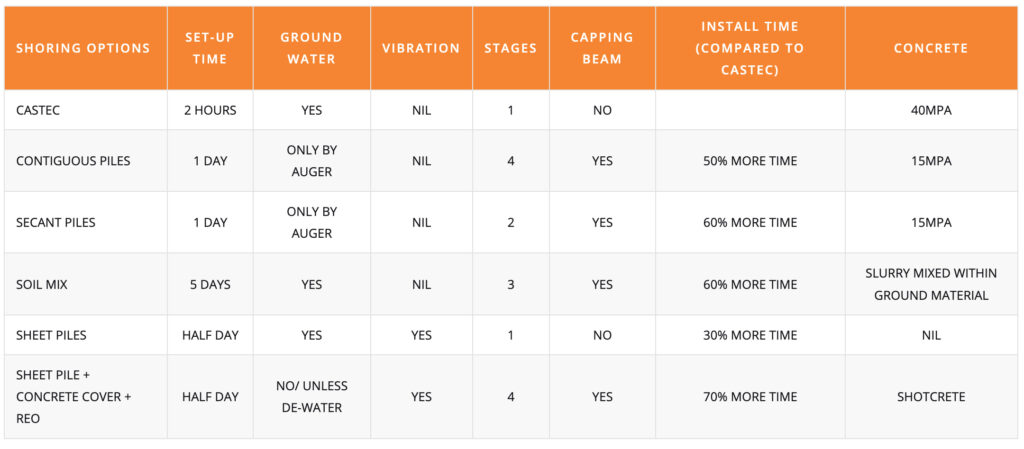

Shoring Wall Comparisons

Is Time Important?

- Install rate 1.lm x 6M Deep Wall in two minutes

- Typically No capping beam required

- Wall finished as soon as it's installed

- Less time to install anchors (three meter center, no walers)

- Cast a wall into water charged ground without loss of concrete

Is Cost Important?

- Less set up cost - typically the day we arrive is the day we start pouring

- Generally each straight length of wall is attempted in one day, subject to site dimensions.

- Typically no capping beam required

- Given the wall is continuous, typically no shotcrete required.

- 40 MPA concrete poured directly by a pump from truck to the mahcine

STRUCTURAL ENGINEERING SNAP SHOT

Standard Wall Specifications:

- Suited to sandy soil sites only

- Shoring wall thickness 300mm

- Depths up to 6m in one pass

- Reinforced concrete 40MPa strength

- Steel fiber additive to concrete mix

- N16 reinforcement bars installed vertically to the centre of the wall.

Fully designed by NER accredited Structural-Geotechnical Engineer

- Structural drawings (inc. Class 2 Regulated Design Lodgement)

- NER Engineer Installation Certificate

Designs Involving

- Cantilever wall set-up (toe in ground below BEL no bracing)

- Full depth design combined with anchors &/or temporary braces

- Works in water charged grounds

- The Castec shoring walls can include a load bearing element for incorporation into final structure as a permanent wall.

- Can bear ontop of rock profile in ground

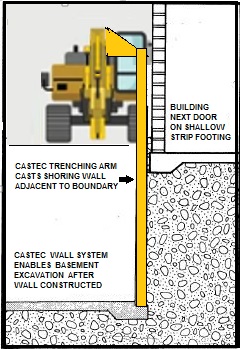

Castec Trenching Arm

Precision

The Castec Shoring Wall system can be cast in-situ within circa 100 mm of adjoining property boundaries.

Cost Effective

Less preparation and less time on-site means reduced cost. Operates in sandy soil sites, no issues with water charged grounds.

WHERE CASTEC CAN BE USED

- Retaining walls for Basement carparks – particularly in unstable sandy soils

- Suitable for both single and double heights basements

- Retaining walls, foundation walls and basement wall system

- Mine shafts and tunnel ports

- Flood levee bank raising projects

- Revetment walls for canals

- Foreshore erosion protection

- Trench shoring for underground services

- Service tunnels – hospitals/race tracks

- Canal construction

- Beach erosion and sea walls

- Underground water tanks

- Cut off walls for contaminated sites

- Road work retaining walls

- Ground stabilisation

- Foundation walls on slip slopes

- Packaged with Helcon Screw Piles for greater load bearing walls